The Global Chip Shortage: Unpacking Economic Repercussions and Finding Solutions Explained

Have you ever wondered what makes your smartphone smart, your car drive, or even your refrigerator keep food fresh and connect to the internet? The answer, in large part, lies in tiny but powerful components called semiconductors, often simply called chips or microchips. These are the "brains" of almost every electronic device we use today.

For the past few years, the world has been grappling with a severe global chip shortage. This isn’t just a minor inconvenience; it’s a massive economic challenge affecting industries worldwide, from car manufacturers to consumer electronics giants, and even healthcare providers.

In this comprehensive guide, we’ll break down what the global chip shortage is, why it happened, its far-reaching economic consequences, and what solutions are being explored to overcome this critical hurdle. We’ll explain everything in easy-to-understand language, perfect for anyone looking to grasp this complex but vital issue.

What Exactly is the Global Chip Shortage?

Imagine you’re trying to bake a cake, but you suddenly run out of flour. You can’t make the cake until you get more flour. In the world of technology, chips are like that essential "flour."

The global chip shortage means there aren’t enough of these crucial semiconductor components being produced to meet the huge demand from various industries. This scarcity leads to delays in manufacturing, higher prices for consumers, and significant disruptions across the global economy.

These chips aren’t just one type of product; they come in thousands of varieties, each designed for specific tasks. From simple power management chips to complex processors that power artificial intelligence, they are all in high demand.

Why Did the Chip Shortage Happen? A Perfect Storm of Factors

The chip shortage isn’t due to a single cause but rather a combination of unfortunate events and long-standing industry practices that created a "perfect storm."

1. The COVID-19 Pandemic and Shifting Demand

- Work-from-Home Boom: When lockdowns began, millions of people suddenly needed new laptops, webcams, and home office equipment. This caused a massive, unexpected surge in demand for chips used in these devices.

- Home Entertainment: People spent more time at home, leading to increased purchases of gaming consoles (like the PlayStation 5 and Xbox Series X), smart TVs, and other consumer electronics.

- Supply Chain Disruptions: Factory closures, travel restrictions, and labor shortages due to the pandemic also hampered the production and transportation of chips and their raw materials.

2. "Just-in-Time" Manufacturing

- Many industries, especially the automotive sector, operate on a "just-in-time" inventory system. This means they order parts only when they need them, keeping very little stock on hand to save costs.

- When the pandemic hit, car manufacturers initially cut their chip orders, expecting a drop in sales. However, demand recovered much faster than anticipated. By the time they tried to reorder, chip factories had already shifted their production to meet the booming demand from tech companies, leaving carmakers at the back of the line.

3. Geopolitical Tensions and Trade Wars

- Trade disputes, particularly between the United States and China, led to restrictions on certain technology companies (like Huawei). This caused some companies to "hoard" chips, buying more than they immediately needed to build up their stock, further straining supply.

4. Natural Disasters and Accidents

- Factory Fires: A major fire at a Renesas Electronics plant in Japan (a key supplier of chips for the automotive industry) significantly reduced production.

- Winter Storms: A severe winter storm in Texas, USA, caused power outages that shut down several semiconductor factories, including those operated by Samsung and NXP.

- Droughts: Taiwan, a major hub for chip manufacturing, experienced severe droughts. Chip fabrication plants use enormous amounts of ultra-pure water, and water shortages impacted their operations.

5. Lack of Manufacturing Capacity

- Building a new semiconductor fabrication plant (or "fab") is incredibly expensive (billions of dollars) and takes years (3-5 years) to complete. There hasn’t been enough investment in expanding capacity quickly enough to meet the sudden surge in demand.

- A few companies, like TSMC (Taiwan Semiconductor Manufacturing Company) and Samsung, dominate the most advanced chip manufacturing, creating a bottleneck.

The Economic Ripple Effect: Who’s Feeling the Pinch?

The chip shortage has sent shockwaves through nearly every sector of the global economy, leading to significant financial losses and impacting consumers directly.

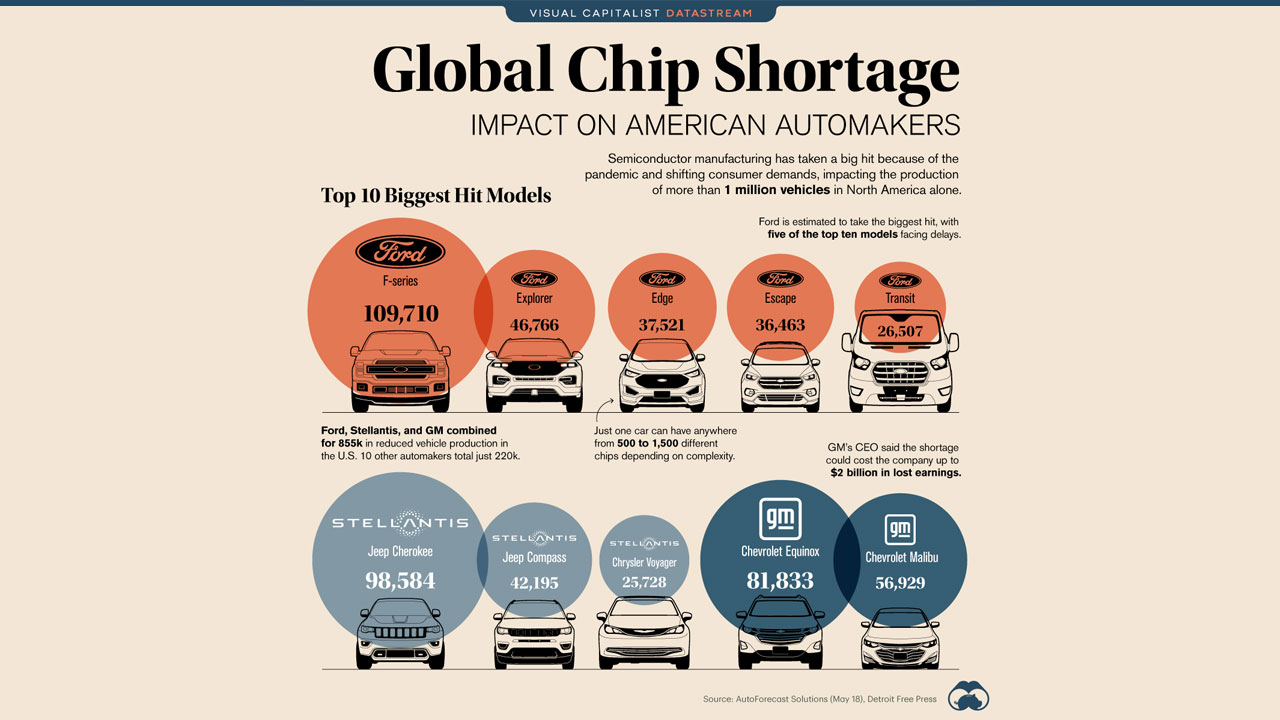

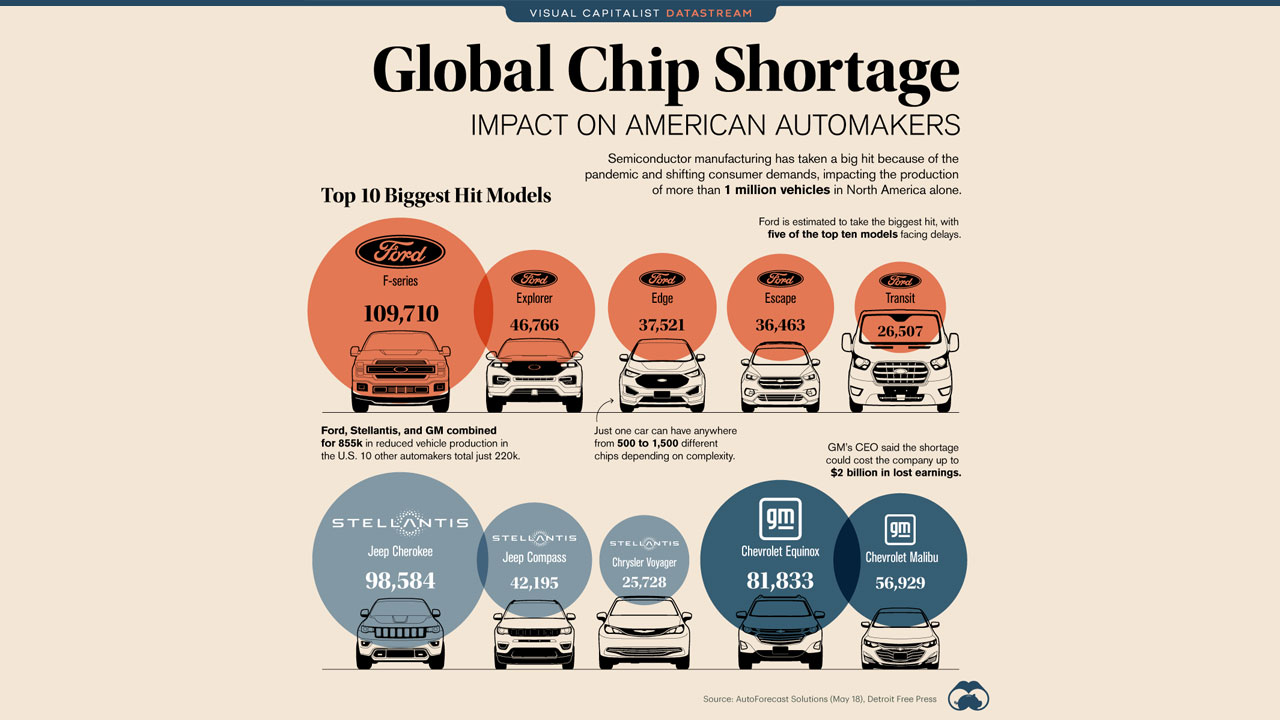

1. Automotive Industry: The Hardest Hit

- Production Cuts: Car manufacturers like Ford, General Motors, Toyota, and Volkswagen have been forced to idle factories and significantly reduce vehicle production. This means fewer new cars are being made.

- Higher Prices: With fewer new cars available, demand for used cars has surged, driving up their prices. New car prices have also increased due and to supply scarcity.

- Lost Revenue: Billions of dollars in potential sales have been lost due to unfinished vehicles sitting in lots, waiting for chips.

2. Consumer Electronics: Delays and Scarcity

- Gaming Consoles: The PlayStation 5 and Xbox Series X have been notoriously difficult to find since their launch, largely due to chip shortages.

- Smartphones and Laptops: While less severe than cars, some models have faced production delays, and prices for certain components have risen.

- Home Appliances: Even smart refrigerators, washing machines, and dishwashers, which increasingly rely on chips for their "smart" features, have experienced production delays.

3. Industrial and Medical Equipment

- Factory Machinery: Chips are vital for robotics and automation in modern factories. Shortages can slow down production in other industries.

- Medical Devices: Essential equipment like MRI machines, ventilators, and diagnostic tools also rely on specialized chips. Delays in their production can have serious public health implications.

4. Inflationary Pressures and Economic Growth

- Increased Costs: The scarcity of chips drives up their prices, and these increased costs are often passed on to consumers in the form of higher prices for finished products. This contributes to overall inflation.

- Slower GDP Growth: When industries can’t produce goods at full capacity, it slows down economic activity and can lead to lower Gross Domestic Product (GDP) growth for nations.

- Job Losses/Furloughs: In some factories forced to reduce output, workers have faced temporary furloughs or even job losses.

5. Innovation and National Security

- Delayed Innovation: Companies might delay research and development into new products if they can’t secure the necessary chips for testing and production.

- National Security Concerns: The reliance on a few key regions for advanced chip manufacturing raises concerns about national security and economic independence, especially for critical infrastructure and defense systems.

Navigating the Storm: Potential Solutions to the Chip Shortage

Addressing the chip shortage is a complex, long-term challenge that requires coordinated efforts from governments, industries, and international collaboration.

1. Increasing Production Capacity

- Building New Fabs: Chipmakers like Intel, TSMC, and Samsung are investing billions of dollars in building new semiconductor fabrication plants in various parts of the world (e.g., Arizona, Ohio, Germany, Japan).

- Challenge: These facilities are incredibly expensive, take years to build and equip, and require highly skilled labor.

- Expanding Existing Fabs: Upgrading and expanding current facilities can offer a quicker, though still significant, boost in output.

2. Government Support and Subsidies

- CHIPS Act (USA): The U.S. government passed the CHIPS and Science Act, providing over $52 billion in subsidies and tax credits to encourage semiconductor manufacturing and research within the United States.

- EU Chips Act (Europe): The European Union has a similar initiative aiming to double its share of global chip production by 2030, investing billions to attract manufacturing.

- Other Nations: Japan, South Korea, and others are also offering incentives to strengthen their domestic chip industries.

3. Diversifying the Supply Chain

- Regional Hubs: Moving away from relying heavily on just a few regions (like Taiwan) for advanced chip manufacturing. Encouraging production in North America, Europe, and other parts of Asia can create a more resilient global supply chain.

- Multiple Suppliers: Companies are working to diversify their suppliers for different types of chips, reducing dependence on a single source.

4. Strategic Inventory Building

- Moving away from a pure "just-in-time" model towards holding a slightly larger "buffer" of essential chips. This can help absorb sudden demand spikes or minor disruptions without bringing entire production lines to a halt.

5. Collaboration and Research & Development (R&D)

- Industry Collaboration: Chipmakers, equipment suppliers, and end-users are working more closely to share information and coordinate production schedules.

- Advanced R&D: Investing in research for new materials, manufacturing techniques, and chip designs can lead to more efficient and sustainable production in the future.

- Talent Development: A critical component is training and attracting enough skilled engineers and technicians to work in these highly complex factories.

The Road Ahead: A Long-Term Perspective

While some immediate pressures from the chip shortage might ease, the underlying issues will take years to fully resolve. Building new fabs, developing skilled workforces, and establishing truly diversified supply chains are long-term projects.

The current crisis has highlighted the critical importance of semiconductors to the global economy and national security. It’s pushing governments and industries to rethink their strategies, prioritizing resilience and security in supply chains alongside efficiency and cost-effectiveness.

The future of technology, manufacturing, and even everyday life hinges on the world’s ability to produce these tiny, indispensable components reliably and in abundance.

Conclusion

The global chip shortage is more than just a temporary hiccup; it’s a profound economic challenge that has exposed vulnerabilities in our highly interconnected world. From impacting car sales and gaming console availability to influencing inflation and national security, its repercussions are far-reaching.

However, the crisis has also sparked unprecedented investment and collaboration aimed at strengthening the semiconductor supply chain. While the road to full recovery will be long and complex, the lessons learned are invaluable. By investing in new production, diversifying supply chains, fostering innovation, and promoting global cooperation, we can build a more resilient and sustainable future for the digital age, ensuring that the "brains" of our modern world are always in good supply.

Post Comment