Navigating the Global Maze: Your Guide to Supply Chain Diversification Strategies

In today’s interconnected yet often unpredictable world, the stability of your business hinges significantly on one critical element: its supply chain. For years, companies chased efficiency and cost savings, often leading to highly concentrated supply networks. Then came a series of seismic events – from the COVID-19 pandemic and the Suez Canal blockage to geopolitical tensions and extreme weather – that ripped through global supply chains, exposing their vulnerabilities.

Suddenly, relying on a single factory in a distant land or a sole shipping route became a risky gamble. This stark reality has propelled Global Supply Chain Diversification Strategies from a niche topic for risk managers to a boardroom imperative.

But what exactly does supply chain diversification mean, and how can businesses, especially those new to this complex landscape, navigate it effectively? This comprehensive guide will break down the essential concepts, strategies, benefits, and challenges in clear, easy-to-understand language.

What is a Supply Chain, and Why Does it Matter So Much Now?

Before we dive into diversification, let’s clarify what a supply chain is.

Imagine your favorite coffee shop. To make your latte, they need coffee beans, milk, sugar, cups, lids, stirrers, and a coffee machine. Each of these items comes from somewhere: beans from a farm, milk from a dairy, cups from a manufacturer. The entire journey of these ingredients, from their origin to your cup, involves a vast network of suppliers, manufacturers, transporters, and distributors. This entire network is the supply chain.

For decades, the focus was on making this chain as lean and cheap as possible. Companies would often find the cheapest supplier, even if it meant relying on just one, far away. This approach, known as "just-in-time" delivery, minimized inventory costs but left little room for error.

Recent events have shown the fragility of this system:

- COVID-19 Lockdowns: Factories shut down, ports closed, and goods couldn’t move.

- Geopolitical Tensions: Trade wars imposed tariffs, and political instability threatened shipping routes.

- Natural Disasters: Floods, earthquakes, and fires disrupted production and logistics.

- Single Points of Failure: Relying on one supplier or one factory meant that if something went wrong there, your entire operation could grind to a halt.

These disruptions highlighted the urgent need for resilience and flexibility in supply chains. Enter diversification.

Understanding Supply Chain Diversification: Don’t Put All Your Eggs in One Basket

At its core, supply chain diversification means spreading out your risks by avoiding over-reliance on a single source, location, or method. Think of it like investing: you wouldn’t put all your savings into one stock, right? You’d diversify your portfolio to minimize risk.

In the context of supply chains, diversification involves:

- Multiple Suppliers: Getting the same component from different companies.

- Multiple Locations: Sourcing from different countries or regions.

- Multiple Logistics Routes: Using different shipping companies or transportation methods.

The goal is to build a supply chain that can withstand shocks, adapt to changes, and keep your business running smoothly, even when one part of the chain faces an issue.

Key Strategies for Global Supply Chain Diversification

Diversifying a supply chain isn’t a one-size-fits-all solution. It requires careful planning and often a combination of strategies. Here are the most common and effective approaches:

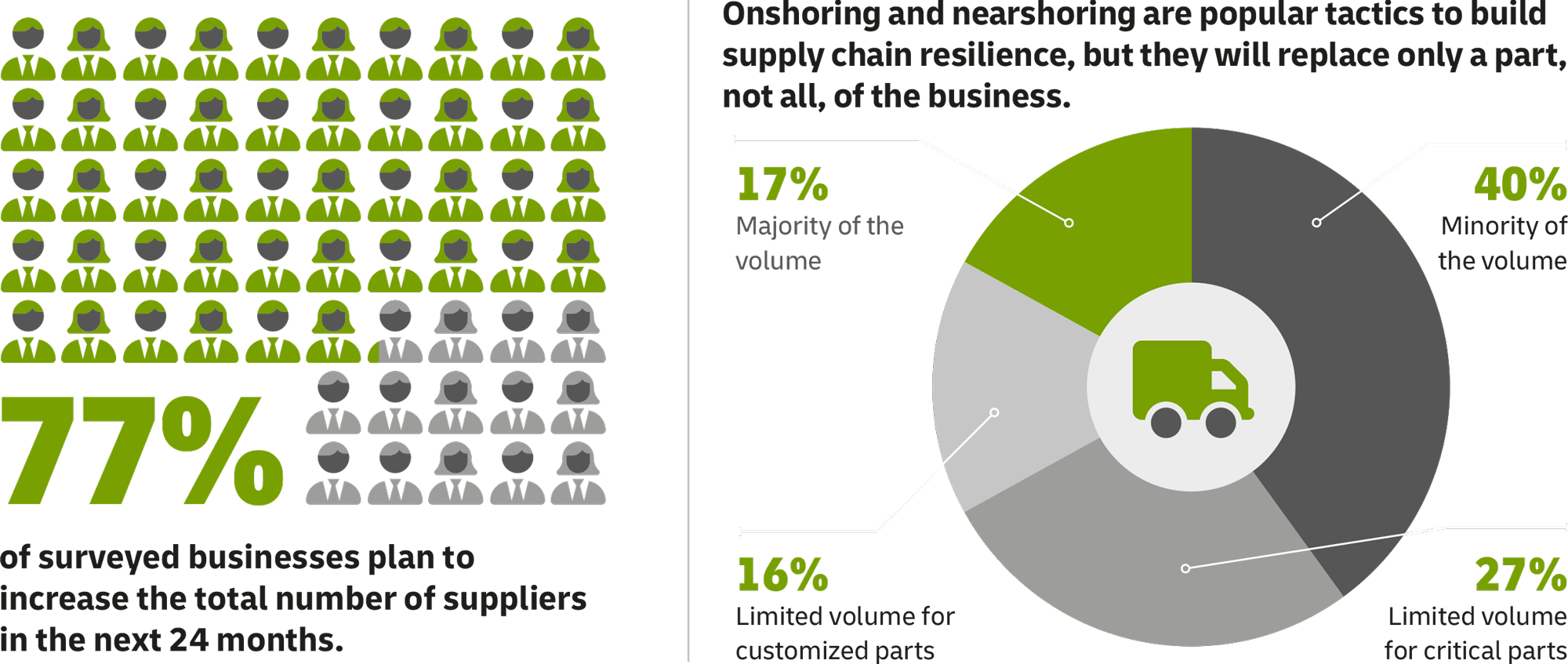

1. Multi-Sourcing (or Dual-Sourcing)

- What it is: Instead of relying on just one supplier for a critical component or raw material, you work with two or more.

- How it helps: If one supplier faces a problem (e.g., a factory fire, labor strike, or quality issue), you can quickly switch to or increase orders from your alternative supplier. This prevents stockouts and production delays.

- Example: An electronics company might buy microchips from both Company A in Taiwan and Company B in South Korea. If a natural disaster hits Taiwan, they can still get chips from South Korea.

- Considerations: It can be more complex to manage multiple supplier relationships and may sometimes mean slightly higher individual unit costs (as you’re not giving all your volume to one supplier for maximum discount).

2. Geographic Diversification (Regionalization, Nearshoring, Reshoring, Friendshoring)

This strategy involves spreading your production and sourcing across different geographic regions to reduce dependence on any single country or area.

-

Regionalization:

- What it is: Focusing on suppliers and manufacturing within a specific region (e.g., North America, Europe, Southeast Asia) rather than globally dispersed.

- How it helps: Reduces long shipping times, lowers transportation costs, and mitigates risks associated with long-distance logistics (like port congestion or geopolitical conflicts far away).

- Example: A European car manufacturer might source most of its parts from within the EU, rather than from Asia or North America.

-

Nearshoring:

- What it is: Moving production or sourcing closer to your main market or headquarters, often to a neighboring country.

- How it helps: Shorter lead times, easier communication (often similar time zones and cultures), reduced shipping costs, and better control over quality and labor practices.

- Example: A U.S. company that previously manufactured in China might move production to Mexico or Canada.

-

Reshoring (or Onshoring):

- What it is: Bringing manufacturing or sourcing operations back to your home country.

- How it helps: Provides maximum control, reduces geopolitical risks, supports local economies, and can enhance a "made in [country]" brand image.

- Considerations: Often involves higher labor costs and may require significant investment in new facilities.

-

Friendshoring (or Ally-Shoring):

- What it is: Sourcing from countries that are considered geopolitical allies or have stable, predictable trade relationships.

- How it helps: Reduces political risks, trade policy uncertainties, and ensures access to critical goods even during times of international tension. It’s about aligning supply chains with national security and foreign policy goals.

- Example: A country might prioritize sourcing critical minerals or technology from a trusted democratic ally rather than a potential geopolitical rival.

3. Vertical Integration

- What it is: Instead of relying on external suppliers for key components or processes, a company acquires or develops the capacity to produce those things internally. This means owning more stages of your supply chain.

- How it helps: Provides greater control over quality, costs, and production schedules. It reduces dependence on external factors and can ensure a steady supply of critical inputs.

- Example: An apparel company might buy a textile mill to produce its own fabrics instead of purchasing them from external suppliers. Or a car company might start producing its own battery cells.

- Considerations: Requires significant investment, can be complex to manage new business units, and may reduce flexibility compared to outsourcing.

4. Technology Adoption & Data Analytics

Technology isn’t a diversification strategy itself, but it’s a powerful enabler for effective diversification.

-

Real-time Visibility:

- What it is: Using sensors (IoT), GPS tracking, and advanced software to see exactly where your goods are at any moment, from raw materials to finished products.

- How it helps: Allows companies to quickly identify disruptions, assess their impact, and activate backup plans. If a ship is delayed, you know immediately and can reroute or activate alternative suppliers.

-

Artificial Intelligence (AI) & Machine Learning (ML):

- What it is: Using AI to analyze vast amounts of data (weather patterns, geopolitical news, supplier performance, demand forecasts) to predict potential disruptions and optimize supply chain routes and inventory levels.

- How it helps: Enables proactive risk management, helps identify the best alternative suppliers, and optimizes inventory placement across diversified locations.

-

Blockchain:

- What it is: A secure, transparent, and unchangeable digital ledger that can track every transaction and movement of goods in a supply chain.

- How it helps: Provides unparalleled transparency and traceability, making it easier to verify the origin of goods, ensure ethical sourcing, and identify bottlenecks or fraudulent activities.

5. Inventory Management & Buffer Stock

- What it is: While "just-in-time" minimizes inventory, diversification often means holding strategic amounts of "buffer stock" or "safety stock" of critical components or finished goods.

- How it helps: Provides a cushion against unexpected disruptions. If a supplier fails or a shipping route is blocked, you have enough stock to continue production or fulfill orders for a period, buying time to resolve the issue.

- Considerations: Holding more inventory costs money (storage, insurance, potential obsolescence), so it requires a careful balance between risk reduction and cost.

6. Supplier Relationship Management & Collaboration

- What it is: Building strong, collaborative relationships with your key suppliers, even the diversified ones. This goes beyond simple transactions to include sharing information, joint planning, and even mutual investment.

- How it helps: Loyal and well-informed suppliers are more likely to prioritize your needs during a crisis. Collaboration can lead to innovations, better risk sharing, and more transparent communication about potential issues.

- Example: Regularly communicating your future needs, sharing market insights, and even helping a smaller supplier invest in new capabilities.

7. Risk Assessment & Scenario Planning

- What it is: Systematically identifying potential risks in your supply chain (e.g., natural disasters in specific regions, political instability, single points of failure) and developing "what-if" scenarios to prepare for them.

- How it helps: Allows businesses to proactively develop contingency plans for various disruptions, ensuring that when a crisis hits, they’re not scrambling to react but rather executing a pre-planned strategy.

- Example: Running simulations to see what happens if a key port closes or a major supplier goes out of business, then developing specific responses for each scenario.

The Benefits of Supply Chain Diversification

While implementing these strategies can seem daunting, the long-term benefits far outweigh the initial challenges:

- Increased Resilience & Stability: Your business becomes better equipped to handle unexpected shocks, ensuring continuity of operations.

- Reduced Risk Exposure: Less reliance on single points of failure means fewer catastrophic disruptions.

- Improved Agility & Responsiveness: A diversified network can adapt more quickly to changing market demands, customer preferences, or unforeseen events.

- Enhanced Cost Savings (Long-term): While initial costs might rise, avoiding costly shutdowns, emergency air freight, or lost sales due to stockouts often leads to significant long-term savings.

- Better Negotiation Power: Having multiple supplier options gives you leverage in negotiations.

- Enhanced Reputation & Customer Loyalty: Businesses that consistently deliver, even during crises, build stronger trust with their customers.

- Sustainability & Ethical Sourcing: Diversification can allow you to choose suppliers that align with your environmental, social, and governance (ESG) goals, reducing reliance on regions with questionable labor or environmental practices.

The Challenges of Supply Chain Diversification

It’s important to acknowledge that diversification isn’t without its hurdles:

- Initial Costs: Setting up new supplier relationships, investing in new factories, or holding more inventory can be expensive upfront.

- Increased Complexity: Managing multiple suppliers, diverse logistics networks, and different regulatory environments adds layers of complexity.

- Quality Control: Ensuring consistent quality across multiple suppliers, especially in different regions, can be challenging.

- Loss of Economies of Scale: Spreading orders among several suppliers might mean you lose out on the steepest volume discounts you’d get from a single large supplier.

- Finding New Suppliers: Identifying, vetting, and onboarding new, reliable partners takes time and resources.

Implementing Diversification: A Step-by-Step Approach for Beginners

Don’t try to diversify everything at once. Start small and strategically:

- Map Your Current Supply Chain: Get a clear picture of every step, every supplier, and every route. Identify your most critical components and your single points of failure.

- Assess Risks: For each critical component or supplier, ask: What could go wrong? What’s the likelihood? What would be the impact?

- Prioritize: Focus on diversifying the most critical components or processes first – those that would shut down your business if disrupted.

- Start Small (Pilot Projects): Instead of overhauling your entire system, pick one or two critical components and implement a diversification strategy (e.g., add a second supplier for one key input).

- Build Relationships: Invest time in vetting potential new suppliers and building strong, transparent relationships with all your partners.

- Invest in Technology: Even simple visibility tools can make a huge difference in managing a diversified supply chain.

- Monitor and Adapt: Supply chains are dynamic. Continuously monitor your risks, supplier performance, and global events, and be prepared to adjust your strategies as needed.

The Future is Diversified

Global supply chain diversification is no longer an optional luxury; it’s a fundamental requirement for business survival and growth in the 21st century. While it demands investment and strategic foresight, the ability to withstand disruptions, adapt to change, and maintain continuous operations will be the hallmark of successful businesses. By embracing these diversification strategies, companies can transform their vulnerabilities into sources of competitive advantage, future-proofing their operations in an ever-changing world.

Post Comment