Mastering Your Stock: A Comprehensive Guide to Inventory Management Best Practices

Imagine running a business where you always have just the right amount of product – never too much gathering dust, and never too little to disappoint a customer. This isn’t a pipe dream; it’s the result of effective inventory management. For any business that deals with physical products, from a small online boutique to a large manufacturing plant, managing inventory effectively is not just an option, but a critical necessity for survival and growth.

This comprehensive guide will walk you through the essential inventory management best practices, breaking down complex concepts into easy-to-understand language. Whether you’re a budding entrepreneur or looking to refine your existing operations, understanding these principles will help you save money, boost efficiency, and delight your customers.

What Exactly is Inventory Management? (The Basics)

At its core, inventory management is the process of overseeing and controlling the flow of goods into and out of your business. This includes everything from purchasing raw materials or finished products, tracking their movement within your warehouse, storing them safely, and eventually shipping them out to customers.

Think of it like managing a bank account for your products. You need to know how much is coming in, how much is going out, and what your current balance is at all times.

Why Are Inventory Management Best Practices Essential?

Good inventory management isn’t just about counting boxes. It directly impacts your bottom line and overall business health in several significant ways:

- Cost Reduction:

- Minimizing Holding Costs: Every item sitting in your warehouse costs money (storage space, insurance, security, potential damage/obsolescence). Best practices help reduce excess stock.

- Avoiding Stockouts: Running out of popular items means lost sales and unhappy customers who might go to a competitor.

- Preventing Overstocking: Having too much slow-moving or obsolete inventory ties up valuable cash that could be used elsewhere.

- Improved Cash Flow: By not having capital tied up in excessive inventory, you free up cash for other business needs like marketing, product development, or expansion.

- Enhanced Customer Satisfaction: Accurate inventory means you can fulfill orders quickly and reliably, leading to happier customers and repeat business.

- Increased Operational Efficiency: Streamlined processes for receiving, storing, and shipping goods save time and reduce errors, making your operations smoother.

- Better Decision-Making: With accurate data, you can make informed decisions about purchasing, pricing, and promotions.

- Reduced Waste and Shrinkage: Best practices help identify and minimize issues like spoilage, damage, theft, or items becoming obsolete.

Key Pillars of Effective Inventory Management

Before diving into specific practices, let’s understand the fundamental pillars that support a robust inventory system:

- Accuracy: Knowing exactly what you have, where it is, and its condition.

- Organization: A well-structured and logical storage system.

- Visibility: The ability to see your inventory levels and movement in real-time.

- Strategy: Using data and techniques to optimize stock levels and flow.

- Control: Implementing processes to prevent errors, theft, and damage.

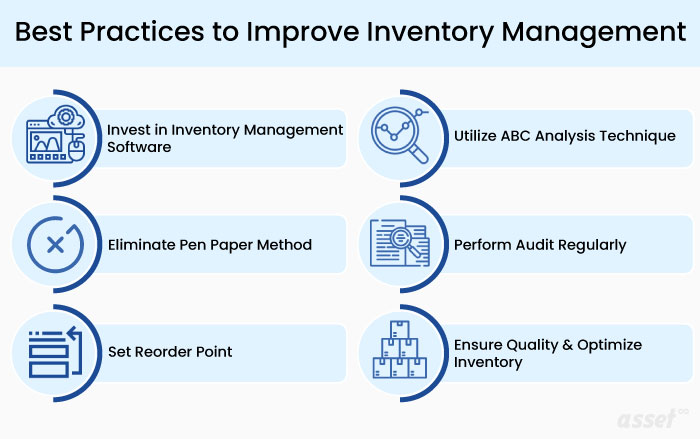

Top Inventory Management Best Practices (Detailed Guide)

Now, let’s explore the practical steps and strategies you can implement to master your inventory.

1. Embrace Technology: Invest in Inventory Management Software (IMS)

For any business beyond the smallest scale, relying on spreadsheets or manual tracking is a recipe for errors and inefficiency. Inventory Management Software (IMS) is the cornerstone of modern inventory control.

What it does: An IMS centralizes all your inventory data. It tracks products from the moment they arrive, through your warehouse, and until they leave. It can automate many tasks, generate reports, and integrate with other business systems (like e-commerce platforms or accounting software).

Benefits:

- Real-time Visibility: Know exactly what you have in stock at any given moment.

- Automation: Automate reorder alerts, purchase orders, and sales updates.

- Accuracy: Reduces human error significantly.

- Reporting: Provides insights into sales trends, popular products, and slow-moving items.

- Scalability: Grows with your business.

Features to Look For:

- Barcode scanning capabilities

- Integration with sales channels (online store, POS)

- Purchase order management

- Reporting and analytics

- Multi-location support (if applicable)

- User-friendly interface

2. Master Data Accuracy and Tracking

Even with software, the data you feed into it must be accurate. This is where meticulous tracking comes in.

- Implement Perpetual Inventory System: This means continuously updating inventory records as items are sold or received. Every transaction (sale, return, receipt, transfer) is recorded immediately.

- How it differs from Periodic: A periodic system only updates inventory at specific intervals (e.g., once a month or year), relying on physical counts. Perpetual is far superior for real-time accuracy.

- Conduct Regular Cycle Counting: Instead of doing one massive, disruptive annual inventory count (physical inventory/stocktake), break it down. Cycle counting involves counting a small, specific portion of your inventory on a regular basis (daily, weekly).

- Benefits: Less disruptive, helps identify errors faster, improves accuracy over time, and reduces the need for full shutdowns.

- Utilize Barcodes or RFID: These technologies are crucial for quick, accurate, and efficient tracking.

- Barcodes: Scannable codes that link to product information in your IMS. Essential for receiving, picking, packing, and shipping.

- RFID (Radio-Frequency Identification): More advanced, allowing multiple items to be scanned simultaneously without line-of-sight. Ideal for high-volume environments.

- Standardize Naming and SKU System: Create a clear, consistent, and logical system for naming your products and assigning Stock Keeping Units (SKUs). This prevents confusion and errors.

- Example SKU: "TSHIRT-M-BLUE-COTTON" is more informative than just "ITEM001."

- Document Standard Operating Procedures (SOPs): Clearly define how every inventory-related task should be performed – receiving, put-away, picking, packing, shipping, returns, and counting. Train all staff on these SOPs.

3. Optimize Your Warehouse Layout & Organization

A messy, disorganized warehouse is a productivity killer and an error generator.

- Logical Flow: Design your warehouse layout so that products move efficiently from receiving, to storage, to picking, to shipping, with minimal backtracking or wasted movement.

- Clear Labeling: Every shelf, bin, and product location should be clearly labeled. This makes it easy for staff to find and put away items quickly.

- Dedicated Zones:

- Receiving Area: Where incoming goods are inspected and processed.

- Put-Away Area: Where new stock awaits placement in its permanent location.

- Storage Area: Organized by SKU, product type, or sales velocity.

- Picking/Packing Area: Where orders are assembled and prepared for shipment.

- Shipping Area: Where packaged orders await pickup.

- Returns/Damaged Goods Area: A separate zone for items needing inspection or disposal.

- Implement FIFO (First-In, First-Out) for Perishable/Date-Sensitive Items: Ensure older stock is sold before newer stock to prevent spoilage or obsolescence. This means storing newer items behind older ones.

- Security: Protect your inventory from theft and damage with proper security measures, controlled access, and appropriate storage conditions (temperature, humidity).

4. Implement Strategic Inventory Control Techniques

Beyond just tracking, these techniques help you make smart decisions about how much to order and when.

- Set Reorder Points and Safety Stock:

- Reorder Point: The specific inventory level at which you should place a new order to avoid stockouts. It considers lead time (time from ordering to receiving) and daily sales rate.

- Safety Stock: A buffer of extra inventory held to prevent stockouts due to unexpected demand spikes or supplier delays. It acts as a cushion.

- Utilize ABC Analysis: Categorize your inventory items based on their value or importance to your business.

- "A" Items: High-value, fast-moving, critical items (e.g., top 20% of items accounting for 80% of sales). These require the most rigorous control and frequent monitoring.

- "B" Items: Medium-value, moderate-moving items.

- "C" Items: Low-value, slow-moving items (e.g., bottom 50% of items accounting for 5% of sales). These require less intense control.

- Benefit: Focus your inventory management efforts where they will have the greatest impact.

- Master Demand Forecasting: Use historical sales data, market trends, seasonality, and promotional plans to predict future customer demand as accurately as possible.

- Methods: Simple moving average, weighted moving average, exponential smoothing, qualitative methods (market research, expert opinion).

- Importance: Accurate forecasts prevent both stockouts and overstocking.

- Calculate Economic Order Quantity (EOQ): A formula that helps determine the ideal order quantity to minimize total inventory costs (holding costs + ordering costs). While a bit more advanced, it’s a powerful tool for optimizing purchasing.

- Implement Batch Tracking / Lot Numbers: For products with expiration dates, safety recalls, or quality control needs, tracking by batch or lot number is crucial. This allows you to pinpoint specific groups of products if an issue arises.

5. Streamline Receiving and Shipping Processes

The entry and exit points of your inventory are critical for accuracy and efficiency.

- Receiving:

- Inspect Immediately: Check incoming shipments against purchase orders for accuracy, quantity, and damage.

- Process Promptly: Get new inventory into its designated storage location quickly. Don’t let it sit in the receiving area.

- Document Everything: Record discrepancies, damage, and receipt dates.

- Shipping:

- Accurate Picking: Ensure the right items and quantities are picked for each order. Barcode scanning during picking is essential.

- Secure Packing: Pack items securely to prevent damage during transit.

- Timely Dispatch: Get orders out the door as quickly as possible to meet customer expectations.

- Shipping Documentation: Generate accurate shipping labels and packing slips.

6. Manage Returns (Reverse Logistics) Effectively

Returns are a part of doing business, and how you handle them impacts customer satisfaction and your bottom line.

- Dedicated Returns Area: Have a specific, organized area for processing returned goods.

- Timely Processing: Inspect returned items quickly to determine if they can be restocked, repaired, or need to be disposed of.

- Clear Return Policy: Communicate your return policy clearly to customers to set expectations.

- Update Inventory: Once an item is deemed re-sellable, update your inventory records promptly.

7. Conduct Regular Audits and Performance Reviews

Continuous improvement is key in inventory management.

- Regular KPI Monitoring: Track key performance indicators (KPIs) to measure the effectiveness of your inventory management.

- Inventory Turnover Rate: How many times your average inventory is sold and replaced over a period. A higher rate usually means more efficient sales.

- Stockout Rate: Percentage of orders that couldn’t be fulfilled due to lack of stock.

- Order Fulfillment Rate/Accuracy: Percentage of orders shipped complete and correctly.

- Inventory Accuracy: Percentage of items where physical count matches system records.

- Holding Costs: The cost of storing inventory over time.

- Analyze Discrepancies: When cycle counts or audits reveal differences between physical stock and system records, investigate the root cause. Was it a receiving error, a picking error, theft, or damage?

- Review and Adjust: Use the data from your KPIs and audits to identify areas for improvement and adjust your strategies, reorder points, and processes accordingly.

8. Foster a Culture of Training and Accountability

Your inventory system is only as good as the people operating it.

- Comprehensive Training: Ensure all staff involved in inventory (receiving, warehouse, sales, customer service) are thoroughly trained on your IMS, SOPs, and best practices.

- Clear Roles and Responsibilities: Everyone should know their specific duties and who is accountable for what.

- Open Communication: Encourage staff to report issues, suggest improvements, and ask questions. Regular team meetings can help keep everyone on the same page.

- Performance Feedback: Provide regular feedback to staff on their accuracy and efficiency.

9. Build Strong Supplier Relationships

Your inventory flow is highly dependent on your suppliers.

- Clear Communication: Maintain open lines of communication regarding order status, potential delays, and product changes.

- Reliability: Work with suppliers who consistently deliver on time and with accurate orders.

- Negotiate Terms: Work to establish favorable payment terms and lead times that support your inventory strategy.

- Diversify (Where Possible): Relying on a single supplier for critical items can be risky. Having backup options can mitigate supply chain disruptions.

Common Challenges in Inventory Management (and How Best Practices Help)

Even with best practices, you’ll encounter challenges. Understanding them helps you prepare.

- Inaccurate Forecasting: Leads to either stockouts or overstocking. Best Practice Help: Strong demand forecasting techniques, safety stock, and regular review of sales data.

- Stockouts and Backorders: Lost sales and frustrated customers. Best Practice Help: Accurate reorder points, safety stock, real-time inventory visibility, and strong supplier relationships.

- Excessive Carrying Costs (Overstocking): Ties up capital, increases risk of obsolescence. Best Practice Help: EOQ, ABC analysis, accurate forecasting, and agile purchasing.

- Manual Processes and Human Error: Slow, prone to mistakes. Best Practice Help: Inventory management software, barcode scanning, clear SOPs, and staff training.

- Lack of Visibility: Not knowing what you have or where it is. Best Practice Help: IMS, perpetual inventory, cycle counting, and clear labeling.

- Shrinkage (Theft, Damage, Obsolescence): Direct loss of product and profit. Best Practice Help: Regular audits, secure storage, FIFO, clear return processes, and vigilant staff.

Getting Started with Inventory Management Best Practices

Feeling overwhelmed? Don’t be. You don’t have to implement everything at once. Here’s a step-by-step approach:

- Assess Your Current State: What are your biggest inventory pain points right now? Where are you losing money or time?

- Set Clear Goals: Do you want to reduce holding costs by 10%? Improve order fulfillment accuracy to 99%?

- Choose Your Technology: Start researching and investing in an IMS that fits your business size and budget. This is often the most impactful first step.

- Standardize Your Data: Clean up your product data, create a consistent SKU system, and start using barcodes.

- Train Your Team: Get everyone on board and educated on the new systems and processes.

- Start Small and Scale Up: Begin with cycle counting for your "A" items, then expand. Implement FIFO for new incoming stock.

- Monitor, Measure, and Adjust: Continuously track your KPIs and be willing to refine your processes as you learn.

Conclusion

Inventory management is a dynamic and ongoing process, not a one-time fix. By consistently applying these best practices – leveraging technology, prioritizing accuracy, optimizing your physical space, employing smart strategies, and empowering your team – you can transform your inventory from a source of stress and cost into a powerful asset that drives efficiency, customer satisfaction, and ultimately, greater profitability for your business. Start implementing these steps today, and watch your stock management become a strategic advantage.

Post Comment