Life Cycle Assessment (LCA): Evaluating Product Impact from Cradle to Grave

Every product we use, from the smartphone in our pocket to the clothes on our back, has a story. It’s a story that begins long before it reaches our hands and continues long after we’re done with it. But what if we could truly understand the environmental cost of that story? What if we could trace its journey from the raw materials pulled from the earth to its eventual disposal or recycling?

This is where Life Cycle Assessment (LCA) comes in. LCA is a powerful, scientific methodology that acts like an environmental detective, uncovering the true footprint of a product, service, or even a system throughout its entire existence. It’s about looking beyond the factory gates and understanding the full "cradle-to-grave" impact.

In a world increasingly focused on sustainability and environmental responsibility, understanding LCA is crucial for businesses, policymakers, and conscious consumers alike. This comprehensive guide will demystify LCA, explaining what it is, why it’s so important, how it works, and what it means for our planet.

What is Life Cycle Assessment (LCA)? The Environmental Detective

At its core, Life Cycle Assessment (LCA) is a systematic and standardized methodology for evaluating the potential environmental impacts associated with a product or service. Think of it as a comprehensive audit of all the inputs (like energy, water, raw materials) and outputs (like emissions, waste, wastewater) that occur at every stage of a product’s life cycle.

Unlike a simple "carbon footprint" which focuses solely on greenhouse gas emissions, LCA takes a much broader view. It considers a wide range of environmental impacts, providing a holistic picture of a product’s true environmental burden.

Key characteristics of LCA:

- Holistic View: It looks at the entire life cycle, not just one phase.

- Systematic: It follows a defined, scientific methodology, often guided by international ISO standards (ISO 14040 and ISO 14044).

- Data-Driven: It relies on quantitative data to measure impacts.

- Comparative: It can be used to compare the environmental performance of different products or processes.

Why is LCA So Important for Sustainability?

In today’s complex global economy, understanding the full environmental impact of products is more critical than ever. Here’s why LCA is an indispensable tool for driving sustainability and making informed decisions:

- Uncovering Hidden Impacts: Many environmental impacts aren’t obvious. For example, the energy used to mine raw materials or the water consumed in textile dyeing might be far greater than the energy used during the product’s actual use phase. LCA reveals these hidden "hotspots."

- Avoiding "Burden Shifting": Without a holistic view, efforts to reduce one environmental impact might inadvertently increase another. For instance, making a product lighter to reduce transport emissions might require more energy-intensive materials. LCA helps prevent such unintended consequences.

- Informing Product Design & Innovation: Designers and engineers can use LCA results to choose more sustainable materials, optimize manufacturing processes, and design products for easier recycling or longer lifespans. This leads to truly eco-friendly products.

- Empowering Informed Decision-Making:

- Businesses: Can identify inefficiencies, reduce costs, enhance brand reputation, and meet regulatory requirements.

- Policymakers: Can develop effective environmental policies, regulations, and incentives.

- Consumers: Can make more conscious purchasing choices by understanding the true impact behind products.

- Combating Greenwashing: In an era of increasing environmental claims, LCA provides credible, science-backed data to support (or refute) a product’s "green" credentials. It helps differentiate genuine sustainability efforts from misleading marketing.

- Supply Chain Optimization: LCA helps companies understand the environmental performance of their suppliers and identify areas for improvement across their entire supply chain.

The Four Phases of an LCA: A Step-by-Step Approach

While complex in practice, the methodology of an LCA is broken down into four distinct, interconnected phases, as defined by the ISO 14040 and ISO 14044 standards:

1. Goal and Scope Definition: Setting the Stage

This is the foundational step. Before any data is collected, the purpose of the LCA must be clearly defined.

- Goal: What question are we trying to answer? (e.g., "Which packaging material has a lower environmental impact?" or "What is the environmental footprint of our new smartphone model?")

- Scope: This outlines the boundaries of the study.

- Product System: What exactly are we evaluating? (e.g., "a single-use plastic bottle" vs. "a reusable water bottle system").

- Functional Unit: This is a crucial concept. It defines the amount of product or service being studied based on its function (e.g., "one liter of drinking water delivered," "100 washes of laundry," "1,000 hours of light"). This allows for fair comparisons between different products that fulfill the same function.

- System Boundaries: What stages of the life cycle are included? (e.g., "cradle-to-gate" – up to the factory gate; "cradle-to-grave" – entire life cycle; "cradle-to-cradle" – incorporating recycling loops).

- Data Quality Requirements: What kind of data is needed, and how reliable must it be?

2. Life Cycle Inventory (LCI): Gathering the Clues

Once the goal and scope are clear, the next phase involves meticulous data collection. This is often the most labor-intensive part of an LCA.

- Data Collection: Researchers gather data on all inputs (raw materials, energy, water) and outputs (emissions to air, water, and soil; waste) associated with each process within the defined system boundaries.

- Modeling: This data is then compiled into a comprehensive inventory, often using specialized LCA software. It quantifies the material and energy flows throughout the entire product system.

- Example: For a T-shirt, LCI data would include:

- Water, pesticides, and fertilizers for cotton farming.

- Energy and chemicals for spinning yarn and weaving fabric.

- Dyes and water for coloring.

- Energy for cutting, sewing, and packaging.

- Fuel for transporting materials and finished products.

- Energy for washing and drying the shirt during its use phase.

- Emissions from incineration or landfill at end-of-life.

3. Life Cycle Impact Assessment (LCIA): Calculating the Damage

The raw data from the LCI phase is just numbers. The LCIA phase translates these numbers into meaningful environmental impacts.

- Classification: LCI data (e.g., CO2 emissions, nitrogen oxides, heavy metals) are assigned to specific "impact categories."

- Characterization: The contributions of each substance to its respective impact category are quantified using scientific models. For example, methane is a much more potent greenhouse gas than CO2, so its impact is weighted accordingly.

- Impact Categories Measured (Examples):

- Climate Change (Global Warming Potential – GWP): Contribution to greenhouse gas emissions (often expressed in CO2 equivalents).

- Resource Depletion: Consumption of non-renewable resources (e.g., fossil fuels, minerals).

- Water Depletion (Water Footprint): Consumption and pollution of freshwater resources.

- Eutrophication: Excessive nutrient enrichment in water bodies, leading to algal blooms and oxygen depletion.

- Acidification: Emissions leading to acid rain.

- Ozone Depletion: Emissions of substances that deplete the stratospheric ozone layer.

- Human Toxicity & Ecotoxicity: Potential harm to human health and ecosystems from toxic substances.

- Land Use: Impact on biodiversity and ecosystems from land transformation.

4. Interpretation: Drawing Conclusions and Making Recommendations

The final phase involves analyzing the results from the LCI and LCIA phases to draw conclusions and provide recommendations.

- Identification of Hotspots: Pinpointing the life cycle stages, processes, or materials that contribute most significantly to the overall environmental impact.

- Sensitivity Analysis: Testing how changes in data or assumptions affect the results.

- Uncertainty Analysis: Quantifying the level of uncertainty in the results due to data variability or modeling assumptions.

- Conclusions and Recommendations: Based on the analysis, the LCA practitioner provides clear conclusions and actionable recommendations for improvement. This might include suggestions for material substitution, process optimization, or end-of-life strategies.

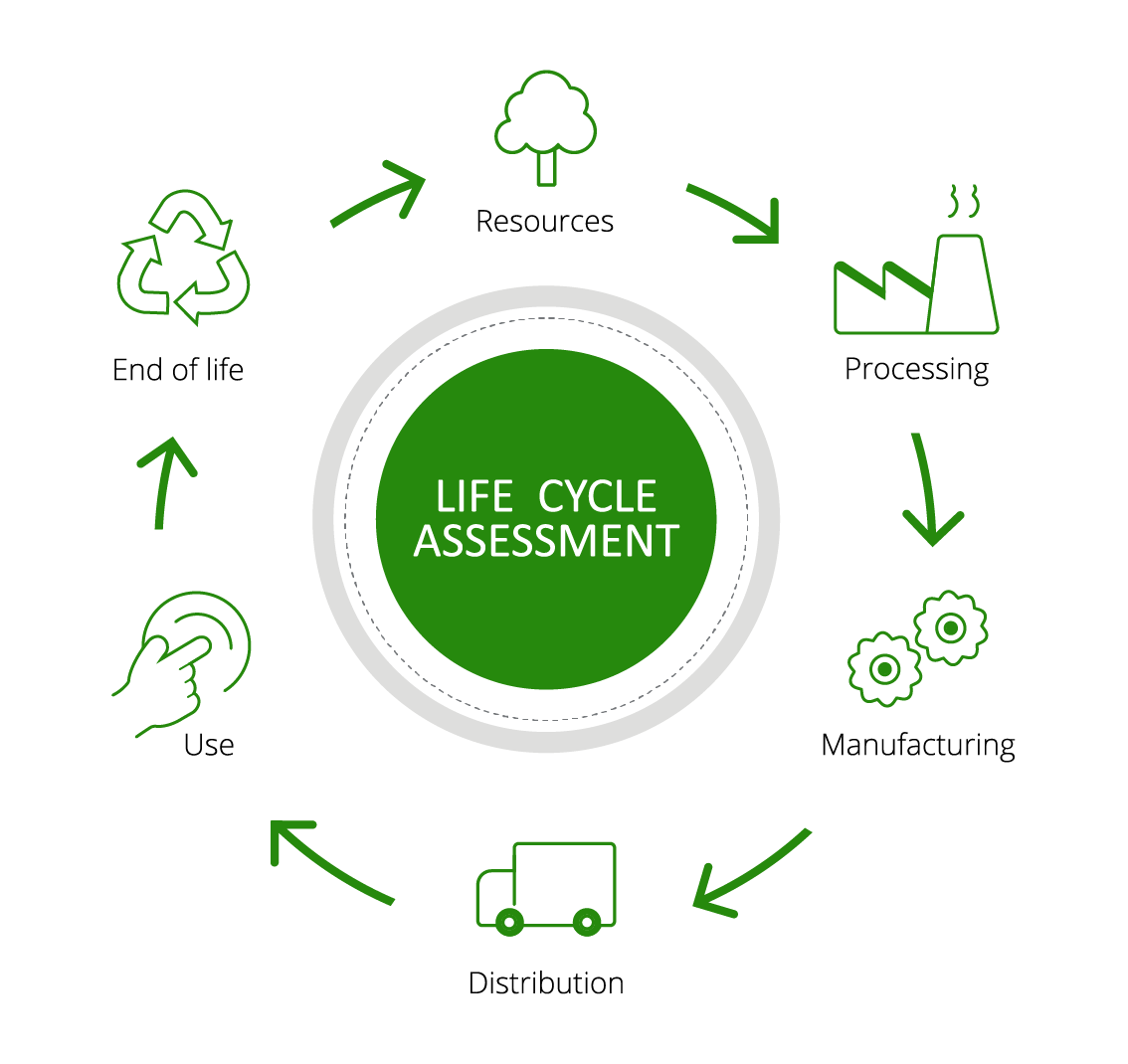

The "Cradle-to-Grave" Journey: Stages of a Product’s Life Cycle

To truly grasp LCA, it helps to visualize the typical stages of a product’s journey:

-

Raw Material Extraction & Processing:

- What happens: Mining, drilling, logging, harvesting, refining, purifying.

- Impacts: Habitat destruction, water pollution, energy consumption, greenhouse gas emissions, land degradation.

- Example: Extracting bauxite for aluminum, drilling for crude oil to make plastic, growing cotton for textiles.

-

Manufacturing & Production:

- What happens: Transforming raw materials into finished products (e.g., shaping, molding, assembling, dyeing, packaging).

- Impacts: High energy consumption, water use, air and water pollution from factory emissions, waste generation, chemical use.

- Example: Assembling electronic components, weaving fabric, molding plastic bottles.

-

Distribution & Transport:

- What happens: Moving raw materials, intermediate products, and finished goods via trucks, ships, trains, and airplanes.

- Impacts: Fuel consumption, greenhouse gas emissions, air pollution (NOx, SOx, particulate matter).

- Example: Shipping goods from a factory in Asia to a retail store in Europe.

-

Use Phase:

- What happens: The product being used by the consumer. This can be a major impact phase for certain products.

- Impacts: Energy consumption (e.g., refrigerators, electronics), water use (e.g., washing machines, showers), consumables (e.g., detergents, printer ink), maintenance.

- Example: The electricity consumed by a TV over its lifetime, the water and detergent used to wash clothes, the fuel consumed by a car.

-

End-of-Life Management:

- What happens: What happens to the product when it’s no longer useful? Disposal, recycling, composting, reuse.

- Impacts:

- Landfilling: Methane emissions (from organic waste), leachate (toxic liquid), land use.

- Incineration: Air pollution, greenhouse gas emissions, ash disposal.

- Recycling: Energy and water consumption for processing, emissions from transport. (Though often much lower impact than virgin material production).

- Composting: Emissions, land use.

- Example: A plastic bottle being recycled into new plastic, clothing being sent to a landfill, food waste being composted.

Who Uses LCA and How?

LCA is a versatile tool used by various stakeholders to advance sustainability:

- Manufacturers and Businesses:

- Product Development: Designing new products with lower environmental impacts.

- Supply Chain Management: Identifying and reducing impacts from raw material sourcing and logistics.

- Marketing & Communication: Substantiating environmental claims (e.g., "this product has a 20% lower carbon footprint").

- Cost Reduction: Identifying energy and material inefficiencies.

- Policy Makers and Governments:

- Environmental Policy: Developing regulations, eco-labels, and incentives for sustainable products.

- Public Procurement: Making greener purchasing decisions for government agencies.

- Waste Management Strategies: Evaluating the best end-of-life options.

- Consumers:

- Informed Choices: Using eco-labels and product information derived from LCAs to choose more sustainable options.

- Researchers and Academics:

- Innovation: Developing new materials and processes with reduced environmental impacts.

- Methodology Improvement: Refining LCA techniques and models.

- Non-Governmental Organizations (NGOs):

- Advocacy: Highlighting environmental issues and promoting sustainable practices.

Benefits of Conducting an LCA

The investment in conducting an LCA yields significant benefits for businesses and the environment:

- Improved Environmental Performance: Directly leads to reduced waste, emissions, and resource consumption.

- Enhanced Brand Reputation and Trust: Demonstrates a genuine commitment to sustainability, building consumer loyalty and investor confidence.

- Competitive Advantage: Differentiates products in the market, attracting environmentally conscious customers.

- Cost Savings: Identifying inefficiencies in material use, energy consumption, and waste management can lead to significant operational savings.

- Innovation and New Opportunities: Encourages the development of novel, more sustainable products and processes.

- Compliance and Risk Management: Helps companies meet current and future environmental regulations, reducing legal and reputational risks.

- Supply Chain Transparency: Provides a deeper understanding of impacts across the entire value chain.

Challenges and Limitations of LCA

While powerful, LCA is not without its challenges and limitations:

- Data Intensity and Availability: Gathering comprehensive, reliable data for every stage of a product’s life cycle can be incredibly complex and time-consuming, especially for global supply chains. Data gaps can lead to assumptions and uncertainties.

- Complexity and Expertise: Performing a robust LCA requires specialized knowledge, trained professionals, and often expensive software tools.

- Boundary Setting: Defining the system boundaries can be subjective and significantly influence the results. What’s included or excluded can change the outcome.

- Uncertainty: LCA results always contain a degree of uncertainty due to data variability, modeling assumptions, and future unknowns (e.g., changes in energy grids).

- Time and Cost: A full, in-depth LCA can be a lengthy and costly undertaking, especially for complex products or large organizations.

- Lack of Social and Economic Aspects: Traditional LCA focuses solely on environmental impacts. While related methodologies like Social LCA (S-LCA) and Life Cycle Costing (LCC) exist, they are separate and not part of a standard environmental LCA.

- Geographic Specificity: Environmental impacts can vary significantly based on location (e.g., energy mix, water scarcity). A generic LCA might not capture these nuances.

LCA and Greenwashing: A Critical Eye

In a world where "green" sells, greenwashing is the act of misleading consumers regarding the environmental practices of a company or the environmental benefits of a product. This can range from vague claims ("eco-friendly!") to selective disclosure of information.

How LCA combats greenwashing:

- Scientific Basis: LCA provides a rigorous, data-driven framework. Claims supported by a comprehensive, peer-reviewed LCA are far more credible than unsubstantiated marketing slogans.

- Holistic Perspective: By looking at the entire life cycle, LCA prevents companies from highlighting one positive aspect while ignoring significant negative impacts elsewhere. For example, a company might claim its product uses recycled content, but an LCA could reveal that its manufacturing process is incredibly energy-intensive.

- Transparency: Reputable LCAs are often published or summarized, allowing for scrutiny and verification. Look for certifications or third-party verified environmental product declarations (EPDs) that are based on LCA.

As consumers, understanding LCA empowers us to be more critical. When you see an environmental claim, ask: "Is this claim backed by science? Does it consider the full life cycle, or just one convenient aspect?"

Looking Ahead: The Future of LCA

The field of Life Cycle Assessment is continually evolving, driven by technological advancements and increasing demands for sustainability:

- Digitization and Automation: Big data, artificial intelligence (AI), and machine learning are making LCAs faster, more accessible, and more accurate by automating data collection and analysis.

- Integration with Circular Economy: LCA is becoming an even more vital tool for designing products for circularity – ensuring materials can be reused, recycled, or composted efficiently at their end-of-life.

- Broader Scope: While environmental LCA is standard, there’s growing interest in integrating social impacts (Social LCA) and economic costs (Life Cycle Costing) to provide a truly holistic "Life Cycle Sustainability Assessment" (LCSA).

- Real-time LCA: The possibility of embedding LCA into product design software and manufacturing processes to provide real-time feedback on environmental performance.

- Standardization and Simplification: Efforts continue to make LCA more standardized across industries and to develop simplified tools that are accessible to a wider range of businesses, particularly small and medium-sized enterprises (SMEs).

Conclusion: LCA as a Cornerstone of a Sustainable Future

Life Cycle Assessment is more than just an academic exercise; it’s a critical framework for understanding and mitigating the environmental impact of everything we produce and consume. By moving beyond superficial assessments and embracing a holistic "cradle-to-grave" perspective, LCA empowers us to:

- Design better products: More efficient, less polluting, and designed for longevity and circularity.

- Make smarter business decisions: Reducing costs, enhancing reputation, and ensuring long-term resilience.

- Develop effective policies: Guiding industries towards greener practices.

- Become more conscious consumers: Making choices that truly align with our values.

As we strive towards a more sustainable future, LCA will continue to be an indispensable tool, helping us navigate the complexities of product impact and build a world where prosperity and planetary health go hand in hand. The journey of every product tells a story – and with LCA, we’re finally learning to read it.

Post Comment